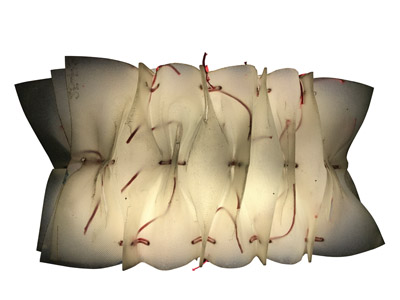

In a research article discussing their initial findings, Blonder and Sharon explained how traditional clay and FRP fabrication are strictly controlled to minimize shrinkage and avoid incompatibilities that could deform the product. “Here, we harness the shrinking phenomenon and its subsequent internal stresses for the generation of complex morphologies,” they stated. A single layer of fibre composite, for instance, contracts in the direction perpendicular to fibre orientation. If you layer a composite with opposite fibre orientations, it will form a saddle-like shape when cured. Another experiment involved sandwiching a low-shrinkage ceramic between layers of higher shrinkage ceramic and cutting opposing grooves in the clay on the outer layers, which resulted in twisted ribbons after firing in an oven.

As part of their work, Blonder and Sharon are attempting to design exterior building panels using 3D software and its parametric design platform, incorporating “a simulation engine that allows the determination of the properties of a sheet in order to emulate its mechanical properties.” Digital panels are divided into smaller squares and, using surface pixelation, each square is given a particular fibre orientation. If you layer two sheets together with different fibre “maps,” the simulator predicts how the squares will contract and thus how the panel will shrink and warp once they do. This simulation can also be done in the inverse — conceiving a particular surface and then determining which fibre orientation map renders it.

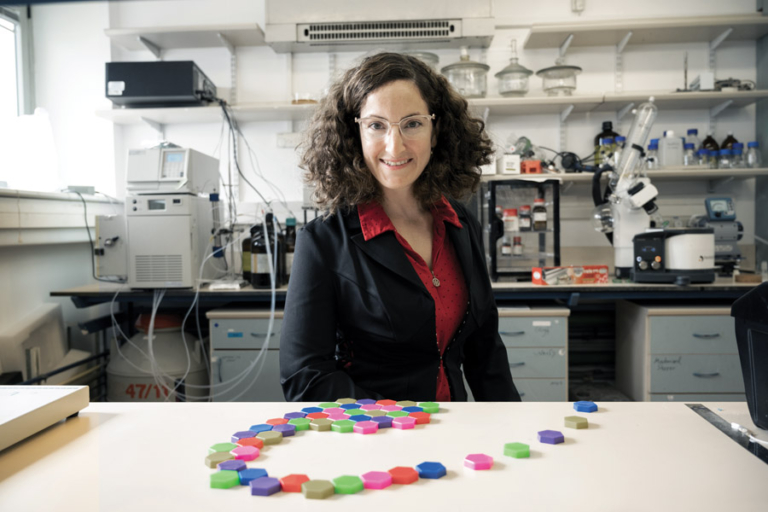

Although Blonder’s research unfolds in the lab, her motivations are firmly rooted in the real world. By exploring the principles and physics of textiles and materials, she is part of a growing architectural movement pushing to transform how we design and build things. To those opposed to increasing plastic production, Blonder paints a bigger picture. FRP is efficient, resilient, durable and requires less framing and infrastructure because of its light weight — all of which could exponentially reduce costs, energy consumption and maintenance. Research into composites made from hemp and flax embedded in organic resins is also advancing and will likely proliferate as demand for FRP increases. All these things, Blonder says, will help integrate FRP into architecture in the future, both as exterior building covers and perhaps even small, lightweight, free-standing shelters.

Many of Blonder’s academic revelations have come through collaborations with colleagues in other fields — cross-pollination that picked up steam during her Azrieli fellowship, which is one of the goals of the program. She hasn’t been teaching much lately because of all her research, but if she could pass on one bit of advice to incoming architecture students, it would be to remain open and receptive to other fields of inquiry. “This is the future,” she says. “Points of convergence are where science becomes exciting and architecture becomes sensible. You have to use multiple languages and multiple approaches to be able to really suggest something valid. Not for today, for tomorrow.”